PLC Programming

Learning / reading about PLC programming because of its importance in industrial manufacturing.

References

- Programmable Logic Controllers, 4th edition; W. Bolton

Preface

Technological advances in recent years have resulted in the development of the programmable logic controller and a consequential revolution of control engineering. This book is an introduction to programmable logic controllers and aims to ease the task of practicing engineers coming first into contact with programmable logic controllers, and also provides a basic course for students on courses such as Nationals and Higher Nationals in Engineering, company training programmes and as an introduction for first year undergraduate courses in engineering.

Programmable Logic Controllers

Controllers

In the traditional

form of control system, the rules governing the control system and when actions are initiated are determined by the wiring. When the rules used for the the control actions are changed, the wiring has to be changed.

Microprocessor controlled system

Instead of hardwiring each control circuit for each control situation, we use the same basic system for all situations if we use a micro-processor based system and write a program to instruct the microprocessor to react to each input signal from, say, switches and give the required outputs to, say, motors and valves, thus we may have a program of the form:

If switch A closes

Output to motor circuit

If switch B closes

Output to valve circuit

By changing the instructions in the program, we can use the same microprocessor system to control a wide variety of situations.

The programmable logic controller

A programmable logic controller (PLC) is a special form of microprocessor-based controller that uses a programmable memory to store instructions and to implement functions such as logic, sequencing, timing, counting, and arithmetic in order to control machines and processes and are designed to be operated by engineers with perhaps a limited knowledge of computers and computing languages. The designers of the PLC have pre-programmed it so that the control program can be entered using a simple, rather intuitive form of language. The term logic is used because programming is primarily concerned with implementing logic and switching operations.

Input devices, e.g. sensors such as switches, and output devices in the system being controlled, e.g. motors, valves, etc., are connected to the PLC. The operator then enters a sequence of instructions, i.e. a program, into the memory of the PLC. The controller then monitors the inputs and outputs according to this program and carries out the control rules for which it has been programmed.

PLCs have the great advantage that the same basic controller can be used with a wide variety of control systems. There is no need to rewire. PLCs are similar to computers, but computers are optimized for calculation whereas PLCs are optimized for control tasks and the industrial environment. PLCs are:

- Rugged and designed to withstand vibration, temperature, humidity and noise

- Have interfacing for inputs and outputs already inside the controller.

- Are easily programmed and have an easily understood programming language which is primarily concerned with logic and switching operations.

The first PLC was developed in 1969.

Hardware

Typically, a PLC system has the same basic functional components of processor unit, memory, power supply unit, input/output interface section, communication interface and programmable device.

- The processor unit or central processing unit (CPU) is the unit containing the microprocessor and this interprets the input signals and carries out the control actions, according to the program stored in memory, communicating the decisions as action signals to outputs.

- The power supply unit is needed to convert the mains A.C. voltage to the low D.C. voltage (5V) necessary for the processor and the circuits in the input and output interface modules.

- The programming device is used to enter the required program into the memory of the processor. The program is developed in the device and then transferred to the memory unit of the PLC.

- The memory unit is where the program is stored that is used for the control actions to be exercised by the microprocessor and data stored from the input for processing and for the output for outputting.

- The input and output sections are where the processor receives information from external devices. The inputs might thus be from switches or from other sensors. Input and output devices can be classified as giving signals which are discrete, digital or analogue. Devices giving discrete or digital signals are ones where the signal is either off or on. Thus a switch is a device giving a discrete signa, either no voltage or a voltage. Digital devices can be considered to be essentially discrete devices which give a sequence of on-off signals. Analogue devices give signals whose size is proportional to the variable being monitored.

- The communications interface is used to recieve and transmit data on communication networks from or to other remote PLCs. It is concerned with such actions as device verification, data acquisition, synchronization between user applications and connection management.

Internal Architecture

The basic internal architecture of a PLC consists of a Central Processing Unit (CPU) containing the system microprocessor, memory, and input/output circuitry. The CPU controls and processes all the operations within the PLC. It is supplied with a clock with a frequency of typically between 1 and 8 MHz. This frequency determines the operating speed of the PLC and provides the timing and synchronization for all elements in the system.

The information within the PLC is carried by means of digital signals. The internal paths along which digital signals flow are called buses. A bus is just a number of conductors along which electrical signals can flow. The CPU uses the data bus for sending data between constituent elements, the address bus to send the addresses of locations for accessing stored data, and the control bus for signals relating to internal control actions. The system bus is used for communications between the input and output ports and the input/output unit.

The CPU

The internal structure of the CPU depends on the microprocessor concerned. In general they have:

- An arithmetic and logic unit (ALU) which is responsible for data manipulation, and arithmetic and logic operations.

- Memory, termed registers, located within the microprocessor and used to store information involved in the program execution.

- A control unit which is used to control the timing of operations.

Information travels in binary form in the form of bits, with 1 and 0 representing on/off states. The term word is used for the group of bits constituting some information. The system has 4 buses:

- The data bus carries the data used in the processing carried out by the CPU. A microprocessor termed as being 8-bit has an internal data bus which can handle 8-bit numbers.

- The address bus is used to carry the addresses of memory locations. Each memory location has a unique address. It is the address bus which carries the information indicating which address is to be accessed.

- The control bus carries the signals used by the CPU for control, e.g. to inform memory devices whether they are to receive data from an input or output data and to carry timing signals used to synchronize actions.

- The system bus is used for communication between the input and output ports and the input/output unit.

Memory

There are several memory elements in PLCs:

- System read-only-memory (ROM) to give permanent storage for the operating system and fixed data used by the CPU.

- Random-access memory (RAM) for the user's program.

- Random-access memory (RAM) for data. This is where information is stored on the status of input and output devices and the values of timers and counters and other internal devices. The data RAM is sometimes referred to as a data table or register table.

- Possibly, as a bolt on extra module, erasable and programmable read-only-memory (RPROM) for ROMs that can be programmed and then the program made permanent.

A battery is used in the PLC to maintain the RAM contents for a period of time. After a program has been developed in RAM it may be loaded into an EPROM memory chip, often a bolt-on module to the PLC, and so made permanent. The storage capacity of a memory unit is determined by the number of binary words it can store. The term byte is used for a word of length 8 bits.

Input/Output Unit

The input/output unit provides the interface between the system and the outside world, allowing for connections to be made through input/output channels to input devices such as sensors and output devices such as motors and solenoids. It is also through the input/output unit that programs are entered from a program panel. Every input/output point has a unique address which can be used by the CPU. The input/output channels provide isolation and signal conditioning functions so that sensors and actuators can often be directly connected to them without the need for other circuitry.

Electrical isolation from the external world is usually by means of optoisolators (the term optocopuler is also often used).

When a digital pulse passes through the light-emitting diode, a pulse of infrared radiation is produced. This pulse is detected by the phototransistor and gives rise to a voltage in that circuit. The gap between the light-emitting diode and the phototransistor gives electrical isolation but the arrangement still allows for a digital pulse in one circuit to give rise to a digital pulse in another circuit.

- The digital signal that is generally comparable with the microprocessor of the PLC is 5 V DC. However, signal conditioning in the input channel, with isolation, enables a wide range of input signals to be applied to it.

- The output from the input/output unit will be digit with a level of 5V. However, after the signal conditioning with relays, transistors or triacs, the output from the output cannel might be a 24 V, 100 mA switching signal, or a DC voltage of 110 V, 1 A or perhaps 240 V, 1 A AC or other.

Outputs are specified as being or relay type, transistor type, or triac type:

- With the relay type, the signal from the PLC output is used to operate a relay and is able to switch currents of the order of a few amperes in an external circuit. The relay not only allows small currents to switch much larger currents but also isolates the PLC from the external circuit. Relays are, however, relatively slow to operate. Relay outputs are suitable for AC and DC switching. They can withstand high currents and voltage transients.

- The transistor type of output uses a transistor to switch current through the external circuit. This gives a considerably faster switching action. It is however, only for DC switching and is destroyed by overcurrent and high reverse voltage. As a protection, either a fuse or built-in electronic protection are used. Optoisolators are used to provide isolation.

- Triac outputs, with optoisolators for isolation, can be used to control external loads which are connected to the AC power supply. It is strictly for AC operation and is very easily destroyed by overcurrent.

Sourcing and Sinking

The terms sourcing and sinking are used to describe the way in which DC devices are connected to a PLC. With sourcing, using the conventional current flow direction as from positive to negative, an input device receives current from the input module, i.e. the input modules is the source of the current. If the current flows from the output module to an output load then the output module is referred to as sourcing. With sinking, using the conventional current flow direction as from positive to negative, an input device supplied current to the input module, i.e. the input module is the sink for the current. If the current flows to the output module from an output load then the output module is referred to as sinking.

There are two common types of mechanical design for PLC systems: a single box, and the modular/rack types.

- The single box type (sometimes called, brick) is commonly used for small programmable controllers and is supplied as an integral compact package with power supply, processor, memory, and input/output units. Such a PLC may have 6-24 inputs and 4-16 outputs and a memory which stores 300 to 1000 instructions.

- Some brick systems have the capacity to be extended to cope with more inputs and outputs by linking input/output boxes to them.

- Systems with larger numbers of inputs and outputs are likely to be modular and designed to fit in racks. The modular type consists of separate modules for power supply, processor, etc., which are often mounted on rails within a metal cabinet. The rack type can be used for all sizes of programmable controllers and has the various functional units packaged in individual modules which an be plugged into sockets in a base rack.

Programming PLCs

Programming devices can be a hand-held device, a desktop console or a computer. Only when a program has been designed on the programming device and is reading is it transferred to the memory unit of the PLC.

- Hand-held programming devices will normally contain enough memory to allow the unit to retain programs while being carried from one place to another.

- Desktop consoles are likely to have a visual display unit with a full keyboard and screen display.

- Personal computers are widely configured as program development work stations. Some PLCs only require the computer to have appropriate software; others require special communication cards to interface with the PLC.

Questions

- The term PLC stands for: D. Programmable Logic Controller

- A transistor output channel from a PLC:

- Is used for only DC switching TRUE

- Is isolated rom the output load by an optocoupler TRUE

- A relay output channel from a PLC:

- Is used for only DC switching: FALSE, Relay outputs are suitable for AC and DC switching

- Can withstand transient overloads: TRUE, They can withstand high surge currents and voltage transients

- A triac output channel from a PLC:

- Is used for only AC output loads TRUE

- Is isolated from the output load by an optocoupler TRUE

- Which of the following is most likely to be the voltage level used internally in a PLC? 5V

- The reason for including optocouplers on input/output units is to:

- Provide a fuse mechanism which breaks the circuit if high voltages or currents occur. TRUE

- Isolate the CPU from high voltages or currents. TRUE

- Draw a block diagram showing in general terms the main units in a PLC.

- SEE BLOCK DIAGAM ABOVE

- Draw a black diagram of a PLC showing the main functional items and how buses link them, explaining the functions of each block.

- SEE NOTES ABOVE

- State the characteristics of the relay, transistor, and triac types of PLC output channels.

- SEE NOTES ABOVE

- How many bits can a 2K memory store?

- 2K * 8 = 16k bits

Input-Output Devices

This chapter is a brief consideration of typical input and output devices used with PLCs. The input devices considered include digital and analogue devices such as mechanical switches for position detection, proximity switches, photoelectric switches, encoders, temperature and pressure switches, potentiometers, linear variable differential transformers, strain gauges, thermistors, thermotransistors, and thermocouples. Output devices considered include relays, contactors, solenoid valves and motors.

Input Devices

The term sensor is used for an input device that provides a usable output in response to a specified physical input. The term transducer is generally used for a device that converts a signal from one form to a different physical form. This sensors are often transducers, but also other devices can be transducers.

Sensors which give digital/discrete outputs can be easily connected to the input ports of PLCs. Sensors which give analogue signals have to be converted to digital signals before inputting them to PLC ports. Defining the performance of sensors:

- Accuracy is the extent to which the value indicated by a measurement system or element may be wrong. The error of a measurement is the difference between the result of the measurement and the true value of the quantity being measured. Errors:

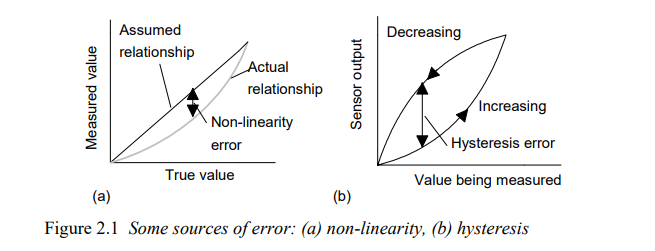

- Non-linearity error: result of deviation from linearity

- hysteresis error: used for the difference in outputs given from the same value of quantity being measured according to whether that value has been reached by a continuously increasing change or a continuously decreasing change.

- The range of variable of system is the limits between which the input can vary.

- The response time is the time which elapses after the input to a system or element is abruptly increased from zero to a constant value up to the point at which the system or element gives an output corresponding to some specified percentage of the input. The rise time is the time taken for the output to rise to some specified percentage of the steady-state output. The settling time is the time taken for the output to settle within some percentage of the steady-state value.

- The sensitivity indicates how much the output of an instrument or system element changes when the quantity being measured changes by some given amount.

- The stability of a system is its ability to give the same output when used to measure a constant input over a period of time. The term *drift( is often used to describe the change in output that occurs over time. The term *zero drift( is used for the changes that occur in output when there is zero input.

- The term repeatability is used for the ability of a measurement system to give the same value for repeated measurements of the same value of a variable.

- The reliability of a measurement system, or element in such a system, is defined as being the probability that it will operate to an agreed level of performance subject to specified environment conditions.

Mechanical Switches

A mechanical switch generates an on-off signal or signals as a result of some mechanical input causing the switch to open or close.

Switches are available with normally open (NO) or normally closed (NC) contacts or can be configured as either by choice of the relevant contacts. The term limit switch is used for a switch which is used to detect the presence or passage of a moving part. It can be actuated by a cam, roller, or lever.

Proximity Switches

Proximity switches are used to detect the presence of an item without making contact to it. The eddy current type of proximity switch has a coil which is energized by a constant alternating current and produces a constant alternating magnetic field. Another type is the reed switch. A proximity switch that can be used with metallic and non-metallic objects is the capacity proximity switch. The proximity of the object is detected by a change in capacitance. The inductive proximity switch consists of a coil wound round a ferrous metallic core.

Photoelectric sensors and switches

Photoelectric switch devices can either operate as transmissive types where the object being detected breaks a beam of light, usually infrared radiation, and stops it reaching the detector or reflective types where the object being detected reflects a beam of light onto the detector. In both types the radiation emitter is generally a light-emitting diode (LED). The radiation detector might be a phototransistor, often a pair of transistors, known as a Darlington pair. Another possibility is a photodiode. Depending on the circuit used, the output can be made to switch to either high or low when light strikes the diode.

Encoder

The term encoder is used for a device that provides a digital output as a result of angular or linear displacement. An incremental encoder detects changes in angular or linear displacement from some datum position, while an absolute encoder gives the actual angular or linear placement. The image below shows a basic for of an incremental encoder for a measurement of angular displacement.

A beam of light, from perhaps a light emitting diode (LED), passes through slots in a disc and is detected by a light sensor, e.g. a photodiode or a phototransistor. When the disc rotates, the light beam is alternatively transmitted or stopped so a pulsed output is produced form the light sensor. The number of pulses is proportional to the number of slots on a disc,

The absolute encoder differs from the incremental encoder in having a pattern of slots which uniquely defines each angular position.

Temperature Sensors

A simple form of temperature sensor which can be used to provide an on-off signal when a particular temperature is reached is the bimetal element. Another form of temperature sensor is the resistive temperature detector (RTD). The electrical resistance of metals or semiconductors changes with temperature. Thermodiodes and thermotransistors are used as temperature sensors since the rate at which electrons and holes diffuse across semiconductor junctions is affected by the temperature.

Another commonly used temperature sensor is the thermocouple. The thermocouple consists essentially of two dissimilar wires A and B forming a junction. When the junction is heated so that it is at a higher temperature than the other junctions in the circuit, which remain at a constant cold temperature, an e.m.f. is produced which is related to the hot junction temperature.

Position/Displacement Sensors

The term position sensor is used for a sensor that gives a measure of the distance between a reference point and the current location of the target, a displacement sensor being one that gives a measure of the distance between the present position of the target and the previously recorded position. Resistive linear and angular position sensors are widely used and relatively inexpensive. There are also linear and rotary potentiometers. The potentiometer thus provides an analogue linear or angular position sensor.

Another form of displacement sensor is the linear variable differentiable transformer (LVDT), this giving a voltage output related to the position of a ferrous rod. Capacitive displacement sensors are essentially just parallel plate capacitors. The capacitance will change if the plate separation changes, the area of overlap of the plate changes, or a slab of dielectric is moved into or out of the plates.

Strain Gauges

When a wire or strip of semiconductors is stretched, its resistance changes. The factional change in resistance is proportional to the fractional change in length, i.e. strain:

where is the change in resistance for a wire of resistance and is a constant called the gauge factor. For metals the gauge factor is about 2 and for semiconductors about 100.

Pressure Sensors

Commonly used pressure sensors which give responses related to the pressure are diaphragm and bellows types. The diaphragm type consists of a thin disk of metal or plastic, secure around its edges. When there is a pressure difference between the two sides of the diaphragm, the center of it deflects. The amount of deflection is related to the pressure difference.

This deflection may be detected by strain gauges attached to the diaphragm, by a change in capacitance between it and a parallel fixed plate, or by using the deflection to squeeze a piezoelectric crystal.

Pressure switches are designed to switch on or off at a particular pressure.

Liquid Level Detector

Pressure sensors may be used to monitor the depth of liquid in a tank. The pressure die to a height of liquid above some level is , where is the density of the liquid and the acceleration due to gravity.

Fluid Flow Measurement

A common form of fluid flow meter is that based on measuring the difference in pressure resulting when a fluid flows through a constriction.

Smart Sensors

The term smart sensor is used for a sensor which is integrated with a required buffering and conditioning circuitry in a single element. The circuitry with the element usually consists of data converters, a processor and firmware, and some form of non-volatile EEPROM memory (electrically erasable programmable read only memory, it is similar to EEPROM).

Output Devices

The output ports a PLC are of the relay type or isolator with a transistor or triac types depending on the devices connected to them which are to be switched on or off. Generally, the digital signal from an output channel of a PLC is used to control an actuator which in turn controls some process. The term actuator is used for the device which transforms the electrical signal into some more powerful action which then results in the control of the process.

Relays

Solenoids form the basis of a number of output actuators. When a current passes through a solenoid a magnetic field is produced and this can then attract ferrous metal components in its vicinity.

One example of such an actuator is the relay, the term contactor being used when large currents are involved.

When the output from the PLC is switched on, the solenoid magnetic field is produced and pulls on the contacts and so closes a switch or switches. The result is that much larger currents can be switched on. Thus, the relay might be used to switch on the current of a motor.

Directional Control Valves

Another example of the use of solenoid as an actuator is a solenoid operated valve. The valve may be used to control the directions of flow of pressurized air or oil and so used to operate other devices such as a piston moving in a cylinder.

Directional control valves are described by the number of ports they have and the number of control positions. A directional control valve with 4 ports and two control positions is referred to as a 4/2 valve.

Motors

A D.C. Motor has coils of wire mounted in slots on a cylinder of ferromagnetic material, this being termed armature. The armature is mounted on bearings and is free to rotate. It is mounted in the magnetic field produced by permanent magnets or current passing through the coils of wire, these being termed field coils. When a current passes through the armature coil, forces act on the coil and result in rotation. Brushes and a commutator are used to reverse the current through the coil every half rotation and so keep the coil rotating. The speed of rotation can be changed by changing the size of the current to the armature coil. The term pulse width modulation (PWM) is used to control the average value of voltage by turning on/off a DC voltage.

Many industrial processes only require the PLC to switch a DC motor on or off. This might be done by using a relay. Sometimes a PLC is required to reverse the direction of rotation of the motor. This can be done using relays to reverse the direction of the current applied to the armature coils.

Another form of DC motor is the brushless DC motor. This uses a permanent magnet for the magnetic field but, instead of the armature coil rotating as a result of the magnetic field of the magnet, the permanent magnet rotates within the stationary coil. With the brushless permanent magnet motor, electronic circuitry is used to reverse the current. The motor can be started and stopped by controlling the current to the stationary coil.

Though AC motors are cheaper, more rugged and more reliable than DC motors, the maintaining of constant speed and controlling that speed is generally more complex than with DC motors. As a consequence, DC motors tend to be more widely used for control purposes.

Stepper Motors

The stepper or stepping motor is a motor that produces rotation through equal angles, the so-termed steps, for each digital pulse supplied to its input. There are two basic forms of stepper motor: the permanent magnet type, with a permanent magnet motor, and the variable reluctance type with a soft steel rotor, Each pole is activated by a current being passed through the appropriate field winding, the coils being such that opposite poles are produced on opposite coils. To drive a stepper motor, so that it proceeds step-by-step to provide rotation, requires each pair of stator coils to be switch on or off in the required sequence when the input is a sequence of pulses. Motors are termed unipolar if they are wired so that the current can only flow in one direction through any particular motor terminal, bipolar if the current can flow in either direction any patricular motor terminal.

Questions

TO BE COMPLETED

Number Systems

The number system used for everyday calculations is the decimal system.

The Binary System

The binary system is based on just two digits: 0 and 1. These are termed binary digits or bits. When a number is represented by this system, the digit position in the number indicates the weight attacked to each digit, the weight increasing by a factor of two. The bit 0 is termed the least significant bit and the highest bit the most significant bit.

Octal and Hexadecimal

A problem with binary numbers is that a comparatively small number requires a large number of digits.

Octal System

The octal system is based on eight digits: 0,1,2,3,4,5,6,7. When a number is represented by this system, the digit position in the number indicates the weight attacked to each digit, the weighting increasing by a factor of 8 as we increase form right to left.

To convert denary numbers to octal we successively divide by 8 and note the remainders. The denary number 15 divided by 8 dives 1 with remainder 7 so the denary number 15 is 17 in the octal system.

Hexadecimal System

The hexadecimal system (hex) is based on 16 digits/symbols: 0,1,2,3,4,5,6,7,8,9,A,B.C.D.E.F. When a number is represented by this system, the digit position in the number indicates that the weight attacked to each digit increases by a factor of 16 as we proceed from right to left. To convert from denary numbers into hex we successively divide by 16 and note the remainders.

An alternative method to convert between binary and denary is the binary coded decimal system (BCD). With this system, each denary digit is coded separately into binary. For example, the binary number 15 has the 5 converted into 0101 and 1 into 0001.

Basic Arithmetic

Binary numbers can be signed with an extra bit. 1 means negative and 0 means positive.

One's and Two's Complements

A binary number has two complements, known as one's complement and two's complement. The one's complement of a binary number is obtained by changing all the 1s in the unsigned number into 0s and 0s into 1s. The two's complement is obtained from the one's complement by adding 1 to the least significant bit of the two's complement.

Floating Point Numbers

Fixed point numbers are ones where there is a fixed location of the point separating integers from factional numbers. Scientific Notation is used for these types of numbers. A floating point number is in the form where is termed the mantissa, is the radix or base and is the exponent or power. With binary numbers, the base is understood to be 2. A computing system needs, in addition to storing the sign, to store the mantissa and the exponent.

PLC Data

Most PLCs operate with a 16-bit word, the term word being used for the group of bits storing some information. INT, LINT, UINT, REAL, LREAL, BOOL and more data types. Time duration, the duration of a process, is represented by the IEC standard using the symbols d for days, h for hours, m for minutes, ms for milliseconds, e.g. T#12d2h5s3ms

.

Questions

TO BE COMPLETED

I/O Processing

The Input/Output unit provides the interface between the PLC controller and the outside world and must therefore provide the necessary signal conditioning to get the signal to the required level and also isolate it from possible electrical hazards such as high voltages.

Input/Output Units

Input signals from sensors and the outputs required for actuating devices can be:

- Analogue, i.e. a signal whose size is related to the size of the quantity being sensed

- Discrete, i.e. essentially just an on-off signal

- Digital, i.e. a sequence of pulses

The CPU must have an input of digital signals of a particular size, normally from 0 to 5V. The output from the CPU is digital, normally 0 to 5V.

The input/output (I/O) units of PLCs are designed so that a range of input signals can be changed into 5V digital signals and so that a range of outputs are available to drive external devices. It is this in-build facility to enable a range of input and outputs to be handled which makes PLCs so easy to use. In the case of rack instruments they are mounted on cards which can be plugged into the racks and so the input/output characteristics of the PLC can thus be changed by changing the cards.

Input Units

The terms sourcing and sinking refer to the manner in which DC devices are interfaced with the PLC. For a PLC input unit, with sourcing it is the source of the current supply for the input device connected to it. With sinking, the input device provides the current to the input unit.

The image below shows the basic input circuit unit for discrete digital DC and discrete AC inputs. Optoisolators are used to provide protection. With the AC input unit, a rectifier bridge network is used to rectify the AC so that the resulting DC signal can provide the signal for use by the optoisolator to give the input signals to the CPU of the PLC. Individual status lights are provided for each input to indicate when the input device is providing a signal.

Analogue signals can be inputted to a PLC if the input channel is able to convert the signal to the digital signal using an analogue-to-digital converter. Multiplexing is used so that one analogue input card is not required per input. In an analogue to digital converter, a single analogue input signal gives rise to on-off output signals along perhaps 8 separate wires.

The term resolution is used for the smallest change in analogue voltage which will give rise to a change in one bit in the digital output.

Output Units

With a PLC output unit, when it provides the current for the output device it is said to be sourcing and when the output device provides the current to the output unit it is said to be sinking.

Output units can be relay, transistor or triac.

Analogue outputs are frequently required and can be provided by digital to analogue converters at the output channel. The input to the converter is a sequence of bits with each bit along a parallel line. A bit in the line 0 gives rise to a certain size output pulse. A bit in the 1 line gives rise to an output pulse twice the size of the 0 line pulse. A bit in the 2 line gives rise to an output pulse twice the size of the line 2 pulse, and so on. All of the outputs add together to give the analogue version of the digital input.

Signal Conditioning

When connecting sensors which generate digital or discrete signals to an input unit, care has to be taken to ensure that the voltage levels match. External signal conditioning is often used to bring analogue signals to a common range and so allow a standard form of analogue input channel to be used. A potential divider can be used to reduce the voltage from a sensor to the required level; the output voltage is:

Amplifiers can be used to increase the voltage level. Amplifiers can be used to increase the voltage level. With the inverting amplifier the output is:

with the non-inverting amplifier:

Often a differential amplifier is needed to amplify the difference between two input voltages. The basic form of an operational amplifier circuit is shown below:

Remote Connections

When there are many inputs and outputs located considerable distances away from the PLC, while it would be possible to run cables from each device to the PLC, a more economical solution is to use input/output modules in the vicinity of the inputs and outputs and use just a single core cable to connect each, over long distances, to the PLC instead of the multicore cable that would be needed without such distant I/O modules.

The cables used for communicating data between remote input/output modules and a central PLC, remote PLCs and the master PLC are typically twisted-pair cabling, often rounded through grounded steel conduit to reduce electrical 'noise'. Coaxial cable enables higher data rates to be transmitted and does not require the shielding of steel conduit. Fibre-optic cabling has the advantage of resistance to noise, small size, and flexibility and is now becoming more widely used.

Serial and Parallel Communications

Serial communication is when data is transmitted one but at a time. Parallel communication is when all the constituent bits of a word are simultaneously transmitted along parallel cables.

Serial communication is used for transmitting data over a long distance because it is cheaper than parallel communication. Internally, PLCs work with parallel communication for efficiency.

Serial Communication Standards

For successful serial communication to occur, it is necessary to specify:

- The voltage levels to be used for signals, i.e. what signal represents a 0 and what represents a 1.

- What the bit patterns being transmitted mean and how the message is built up.

- The speed at which the bit pattern is to be sent.

- Synchronization of the clocks at each end.

- Protocols, of flow controls, to enable such information as

able to receive data

ornot able to receive data

to be received. - Error-checking to enable a bit pattern to be checked to determine if corruption of the data has occurred during transmission.

The most common standard serial communication interface used is the RS232. The term baud rate is used to describe the transmission rate, it being approximately the number of bits transmitted or received per second. Flags are bits sent to denote the start and stop of data sending and whether data has been corrupted.

Parallel Standards

The standard interface most commonly used for parallel communications is IEEE-488. This was originally developed by Hewlett Packard to link their computers and instruments and was known as the Hewlett Packard Instrumentation Bus. It is now termed the General Purpose Instrument Bus.

Protocols

It is necessary to exercise control of the flow of data between two devices so what constitutes the message, and how the communication is to be initiated and terminated, is defined. This is termed the protocol.

One form of checking for errors in the message that might occur as a result of transmission is the parity check. This is an extra bit added to a message to ensure that the number of bits in a piece of data is always odd or always even.

ASCII Codes

The most widely used code for the transmission of characters is the ASCII code.

Networks

The increasing use of automation in industry has led to the need for communications and control on a plant-wide basis with programmable controllers, computers, robots, and CNC machines interconnected. The term local area network (LAN) is used to describe a communications network designed to link computers and their peripherals within the same building or site.

Networks can take three forms:

- The star form, the terminals are each connected to a central computer, termed the host, or master with the terminals being termed slaves. The host contains the memory, processing, and switching equipment to enable the terminals to communicate.

- With the bus or single highway type of network, each of the terminals is linked into a single cable and so each transmitter/receiver has a direct path to each other transmitter/receiver in the network.

- With the ring network, a continuous cable, in the form of a ring, links all the terminals.

Distributed Systems

Often PLCs figure in an entire hierarchy of communications. Thus at the lowest level we have input and output devices such as sensor and motors interfaced through I/O interfaces with the next level. The next level involves controllers such as small PLCs or small computers, linked through a network with the next level of larger PLCs and computers exercising local area control. There is increasing use made of systems that can both control and monitor industrial processes. This involves control and the gathering of data. The term SCADA, which stands for supervisory control and data acquisition system is widely used for such a system.

Network Standards

In order to facilitate communications between different devices, the International Standards Organization (ISO) in 1979 devised a model to be used for standardization for open systems interconnection (OSI); the model is termed the ISO/OSI model. A communication link between items of digital equipment is defined in terms of physical, electrical, protocol and user standards, the ISO/OSI model breaking this down into seven layers:

- Physical Medium

- This layer is concerned with the coding and physical transmission of information. Its functions include synchronizing data transfer and transferring bits of data between systems.

- Data Link

- This layer defines the protocols for sending and receiving information between systems that are directly connected to each other. Its functions include assembling bits from the physical layer into blocks and transferring them, controlling the sequence of data blocks and connecting errors.

- Network

- This layer defines the switching that routes data between systems in the network.

- Transport

- This layer defines the protocols responsible for sending messages form one end of the network to the other. It controls message flow.

- Session

- This layer provides the function to set up communications between users at separate locations.

- Presentation

- This layer assures that information is delivered in an understandable form.

- Application

- This layer has the function of linking the user program into the communication process and is connected with the meaning of the transmitted information.

Processing Inputs

A PLC is continuously running through its program and updating it as a result of input signals. Each such loop is termed a cycle. PLCs could be operated by each input being examined as it occurred in the program and its effect on the program determined and output continuously changed. This mode of operation is termed continuous updating, To allow a more rapid execution of a program, a specific area of RAM is used as a buffer store between the control logic and the input/output unit. Each input/output has an address in this memory. At the start of each program cycle the CPU scans all the inputs and copies their status into the input/output addresses in RAM. As the program is executed the stored input data is read from the RAM and the logic operations carried out. The resulting output signals are stored in the reserved input/output section of RAM. At the end of each program cycle all the outputs are transferred from RAM to the appropriate output channels. The outputs then retain their status until the next updating. This method of operation is termed mass I/O copying.

The time taken to complete a cycle of scanning inputs and updating outputs according to their program instructions, i.e. the cycle time, though relatively quick, is not instantaneous and means that the inputs are not watched all the time but samples of their states are taken periodically. The cycle time for a PLC is determined by the CPU speed, the size of the program to be scanned, the number of inputs or outputs to be read, and the system functions that are in use, the greater the number the slower the scanning time.

I/O Addresses

The PLC has to be able to identify each particular input and output. It does this by allocating addresses to each input and output.

Questions

TO BE COMPLETED

Ladder and Functional Block Programming

Programs for microprocessor-based systems have to be loaded into them in machine code, this being a sequence of binary code numbers to represent the program instructions. However, assembly language based on the use of mnemonics can be used. Programming languages can be made even easier by the use of the so-called high level languages, e.g. C, BASIC, PASCAL, FORTRAN, COBOL. PLCs are intended to be used by engineers without any great knowledge of programming. As a consequence, ladder programming was developed. This is a means of writing programs which can be converted into machine code by some software for use by the PLC microprocessor.

The standard for Ladder programming is IEC 1131-3. The IEC 1131-3 programming languages are ladder diagrams (LAS), instruction list (IL), sequential function charts (SFC), structured text (ST), and function block diagrams.

Ladder Diagrams

The image below shows two different ways of drawing the same circuit. The circuit shown on the right is termed a ladder diagram.

With such a diagram the power supply for the circuits is always shown as two vertical lines with the rest of the circuit as horizontal lines. The power lines, or rails as they are often termed, are like the vertical sides of a ladder with the horizontal circuit lines like the rungs of the ladder. The horizontal rungs show only the control portion of the circuit.

With ladder diagrams, no attempt is made to show the actual physical locations (of the circuit components) and the emphasis is on clearly showing how the control is executed.

PLC Ladder Programming

A very commonly used method of programming PLCs is based on the use of ladder diagrams. The ladder diagram consists of two vertical lines representing the power rails. Circuits are connected as horizontal lines, i.e. the rungs of the ladder, between those two verticals.

Ladder Diagram Conventions:

- The vertical lines of the diagram represent the power rails between which circuits are connected. The power flow is taken to be from the left-hand vertical across a rung.

- Each run on the ladder defines one operation in the control process.

- A ladder diagram is read from left to right and from top to bottom. The procedure of going through all the rungs of the program is termed a cycle. The end rung might be indicated with the word END or RET for return, since the program promptly returns to its beginning.

- Each rung must start with an input or inputs and must end with at least one output.

- The term input is used for a control action, such as closing the contacts of a switch, used as . The term output is used for a device connected to the output of a PLC, a motor.

- Electrical devices are shown in their normal condition/

- Thus a switch which is normally open until some object closes it, is shown as open on the ladder diagram.

- A particular device can appear in more than one rung of a ladder, e.g. a relay which switches on one or more devices. The same letters and/or numbers are used to label the device in each situation.

- The inputs and outputs are all identified by their addresses, the notation used depending on the PLC manufacturer.

Logic Functions

Latching

There are often situations where it is necessary to hold an output energized, even when the input ceases. The term latch circuit is used for the circuit used to carry out such an operation. It is a self-maintaining circuit in that, after being energized, it maintains that state until another input is received. Latching is used with start-ups so that the initial switch on of an application becomes latched on.

Multiple Outputs

With ladder diagrams, there can be more than one output connected to a contact.

Entering Programs

Each horizontal rung on the ladder represents an instruction in the program to be used by the PLC. The entire ladder gives the complete program. Whatever method is used to enter the program into a programming terminal or computer, the output to the memory of the PLC has to be in the form that can be handled by the microprocessor. This is termed machine language and is just binary code.

Ladder Symbols

One method of entering the program into the programming terminal involves using a keypad having keys with symbols depicting the various elements of the ladder diagram and keying them in so that the ladder diagram appears on the screen of the programming terminal. The terminal translated the program drawn on the screen into machine language.

Function Blocks

The term function body diagram (FBD) is use for PLC programs described in terms of graphical blocks. It is described as being a graphical language for depicting signal and data flows through blocks, these being reusable software elements. A function block is a program instruction unit which, when executed, yields one or more output values.

Function blocks can have standard functions, such as those of the logic gates or counters or times, or have functions defined by the user.

Logic Gates

Programs are often concerned with logic gates.

Boolean Algebra

Ladder programs can be derived from Boolean expressions since we are concerned with a mathematical system of logic. In Boolean algebra, there are just two digits, 0 and 1.

- , A AND B

- , A OR B

- , NOT A

Questions

TO BE COMPLETED

IL, SFC, and ST Programming Methods

Instruction Lists

A programming method, which can be considered to be the entering of a ladder program using text, is instruction lists (IL). Instruction list gives programs which consist of a series of instructions, each instruction being on a new line. An instruction consists of an operator followed by more operands, i.e. the subjects of the operator. Each instruction may either use or change the value stored in a memory register.

IEC 1131-3 Operators | Mitsubishi | OMRON | Siemens/ | Operation | Ladder diagram |

|---|---|---|---|---|---|

LD | LD | LD | A | Load operand into result register | Start a rung with open contacts |

LDN | LDI | LD NOT | AN | Load negative operand into result register | Start a rung with closed contacts |

AND | AND | AND | A | Boolean AND | A series element with open contacts |

ANDN | ANI | AND NOT | AN | Boolean AND with negative operand | A series element with closed contacts |

OR | OR | OR | O | Boolean OR | A parallel element with open contacts |

ORN | ORI | OR NOT | ON | Boolean OR with negative operand | A parallel element with closed contacts |

ST | OUT | OUT | = | Store result register into operand | An output |

Labels can be used to identify various entry points to a program, useful as we will find later for jumps in programs, and these precede the instruction and are separated from it by a colon:

PUMP_OK: LD C (* Load C *)

LD A (*Load A*)

ANDN B (*AND NOT B*)

Ladder Programs and Instruction Lists

Sequential Function Charts

The term sequential function chart (SFC) is used for a pictorial representation of a system's operation to show the sequence of the events involved in its operation. SFC charts have the following elements:

- The operation is described by a number of separate sequentially connected states or steps which are represented by rectangular boxes, each representing a particular state of the system being controlled.

- Each connecting line between states has a horizontal bar representing the transition condition that has to be realized before the system can move from one state to the next. Two states can never be directly connected, they must always be separated by a transition. Two transitions can never directly follow each other, they must be separated by a step.

- When the transfer conditions to the next state are realized then the next state or step ion the program occurs.

- The process thus continues from one state to the next until the complete machine cycle is completed.

- Outputs/actions at any state are represented by horizontally linked boxes that occur when that state has been realized.

Structured Text

Structured text is a programming language that strongly resembles the programming language PASCAL. Programs are written as a series pf statements separated by semicolons. The statements use predefined statements and subroutines to change variables, these being defined values, internally stored values or inputs and outputs.

Assigned statements are used to indicate how the value of a variable is to be changed;

Light := SwitchA;is used to indicate that a light is to have its 'value' changed, i.e. switched on or off, when switch A changes its 'value', i.e. is on or off.

IF ... THEN ... ELSE is used when selected statements are to be executed when certain conditions occur. FOR and WHILE loops exist as well. You can define variables and types.

Questions

TO BE COMPLETED

Internal Relays

Internal relays are also called auxiliary relays, markers, flags, coils, bit storage. These are one of the elements giving special built-in functions with PLCs and are very widely used in programming. A small PLC might have a hundred or more internal relays, some of them being battery backed so that they can be used in situations where it is necessary to ensure safe shutdown of plant in the event of a power failure.

Internal Relays

In PLCs these are elements that are used to hold data, i.e. bits, and behave like relays, being able to be switched on or off and switch other devices on or off. Hence the term internal relays. Such internal relays do not exist as real-world switching devices but behave in the same way as relays. For programming, they can be treated in the same way as an external relay output and input. Thus inputs to external switches can be used to give an output from an internal relay. This ten results in the internal relay contacts being used, in conjunction with other external input switches, to give an output.

In using an internal relay, it has to be activated on one rung of a program and then its output used to operate switching contacts on another rung, or rungs, of the program. Internal relays can be programmed with as many sets of associated contacts as desired.

To distinguish internal relay outputs from external relay outputs, they are given different types of addresses.

Ladder Programs

With ladder programs, an internal relay output is represented using the symbol for an output device, namely ( ), with an address which indicates that it is an internal relay rather than an external relay.

Battery-backed Relays

If the power supply is cut off from a PLC while it is being used, all the output relays and internal relays will be turned off. Thus when the power is restored, all the contacts associated with those relays will be set differently from when the power was on. Thus, if the PLC was in the middle of some sequence of control actions, it would resume at a different point in the sequence. To overcome this problem, some internal relays have battery back-up so that they can be used in circuits to ensure a safe shutdown of plant in the event of a power failure and so enable it to restart in an appropriate manner. Such battery-backed relays retain their state of activation, even when the power supply is off. The relay is said to have been made retentive. The term retentive memory coil is frequently used for such elements.

One-Shot Operation

One of the functions provided by some PLC manufacturers is the ability to program an internal relay so that its contacts are activated for just one cycle, i.e. one scan through the ladder program. Hence it provides a fixed duration pulse at its contacts when operated. This function is often termed one-shot.

Set and Reset

Another function which is often available is the ability to set and reset an internal relay. The set instruction causes the relay to self-hold, i.e. latch. It then remains in that condition until the rest instruction is received. The term flip-flop is often used.

Master Relay

When large numbers of outputs have to be controlled, it is sometimes necessary for whole sections of ladder diagrams to be turned on or off when certain criteria are realized. This could be achieved by including the contacts of the same internal relay in each of the rungs so that its operation affects all of them. An alternative is to use the master control relay.

Questions

TO BE COMPLETED

Jump and Call

The hump instruction enables part of a program to be jumped over and the way in which subroutines in ladder programmes can be called up. Subroutines enable commonly occurring operations in a program to be repeatedly called up and used over again.

A function often provided with PLCs is the conditional jump. We can describe this as:

IF (some condition occurs) THEN

perform some instructions

ELSE

perform some other instructions

Such a facility enables programs to be designed such that if certain conditions are met then certain events occur, if they are not met then other conditions occur.

Subroutines

Subroutines are small programs to perform specific tasks which can be called for in larger programs. Thus with a Mitsubishi program we might have the situation shown below. When input 1 occurs, the subroutine P is called. This is then executed, the instruction SRET indicating its end and the point at which the program returns to the main program. To clearly indicate where the main program ends the FEND instruction is used.

Questions

TO BE COMPLETED

Timers

In many control tasks there is a need to control time. A motor or pump might need to be controlled to operate for a particular interval of time, or perhaps be switched on after some time interval. PLCs thus have timers as built-in devices. Timers count fractions of seconds or seconds using the internal CPU clock.

- on-delay timers: come on after a particular time delay

- off-delay timers: are on for a fixed period of time before turning off

- pulse timer: The timer switches on or off for a fixed period of time

Programming Timers

All PLC have delay-on timers, small PLCs possibly having only this type of timer. Timers can be linked together, the term cascaded is used, to give longer delay times than are possible with just one timer.

Questions

TO BE COMPLETED

Counters

Counters are provided as built-in elements in PLCs and allow the number of occurrences of input signals to be counted. This might be where items have to be counted as they pass along a conveyor belt, or the number of revolutions of a shaft, or perhaps the number of people passing through a door.

Forms of Counter

A counter is set to some preset number value and, when this value of input pulses has been received, it will operate its contacts. Thus normally open contacts will be closed, normally closed contacts opened.

There are two types of counters. Down-counters count down from the preset value to zero, i.e. events are subtracted from the set value. When the counter reaches the zero value, its contacts change state. Most PLCs offer down counting. Up-counters count from zero up to the preset value, i.e. events are added until the number reaches the preset value. When the counter reaches the set value, its contacts change state.

Counters can be considered to consist of two elements: one relay coil to count input pulses and one to reset the counter, the associated contacts of the counter being used in other rungs.

Questions

TO BE COMPLETED

Shift Registers

The term register is used for an electronic device in which data can be stored. An internal relay is such a device. The shift register is a number of internal relays grouped together which allow stored buts to be shifted from one relay to another.

Shift Registers

A register is a number of internal relays grouped together, normally 8, 16, or 32. Each internal relay is either effectively open or closed, these states being designated as 0 or 1. The term bit is used for each such binary digit. Registers can be used for storing data that originate from input sources other than just simple, single on-off devices such as switches.

With the shift register, it is possible to shift stored bits. Shift registers require three inputs, one to load data into the first location of the register, one as the command to shift data along by one location, and one to reset of clear the register of data.

Questions

TO BE COMPLETED

Data Handling

Timers, counters, and individual internal relays are all concerned with the handling of internal bits, i.e. single on-off signals. Shift registers involve a number of bits with a group of internal relays being linked. The block of data in the register is manipulated. This chapter is about PLC operations involving blocks of data representing a value, such blocks being termed words. A block of data is needed if we are to represent numbers rather than just a single on-off input. Data handling consists of operations involving moving or transferring numeric information stored in one memory word location to another word in a different location, comparing data values and carrying out simple arithmetic operations.

Registers and Bits

A register is where data can be stored. Each data register can store a binary word of 16 or 32 bits. The number of bits determines the size of the number that can be stored. The binary system uses only two symbols, 0 and 1. The binary coded decimal (BCD) format is used with PLCs when they are connected to devices such as digital displays.

Closed Loop Control

Closed loop control of some variable, e.g. the control of the temperature of a room, is achieved by comparing the actual value for a variable with the desired set value and then giving an output, such as switching on a heater to reduce the difference. A controller then takes this difference signal and gives an output to give a response to correct the discrepancy. Such as system is called closed-loop control.

- With proportional control, the controller gives the output to the actuator which is proportional to the difference between the actual value and the set value of the variable.

- Proportional control has a disadvantage in that, because of time lags inherent in the system, the correcting signal applied to the actuator tends to cause the variable to oscillate about the set value. What is needed is a correcting signal which is reduced as the variable gets close to the set value.

- This is obtained by PID control, the controller giving a correction signal which is computed from a proportional element, the P term, an element related to previous values of the variable, the integral I term, and an element which is related to the rate at which the variable is changing, the D term.

- With integral control, the controller output is proportional to the integral of the error with time, i.e. the area under the error-time graph:

- With derivative control, the controller output is proportional to the rate at which the error is changing, i.e. the the slope of the error time graph

- The term tuning is used for determining the optimum values of , , and to be used for a particular control system.

Comments

You can read more about how comments are sorted in this blog post.

User Comments

There are currently no comments for this article.