Automation Engineering

I want to learn more about automation engineering. As a mechanical engineering major, I think one my biggest weaknesses is the understanding of the electrical/software components of machines, which is why I want to learn more about it.

References

- Automation Engineering; Yuri A.W. Shardt; Version 4.0

Forward

This book will examine the foundations of automation engineering in a world increasingly focused on the development and implementation of automation. It will provide the reader with an understanding of the key principles and components of automation engineering and how these principles can be combined and implements in a real industrial system to provide safe, economically viable, and efficient systems.

Introduction to Automation Engineering

Automation engineering is an important component of modern industrial systems that focuses on the development, analysis, optimization, and implementation of complex systems to provide safe, economically viable, and efficient processes. Automation engineering seeks to eliminate as much as possible human intervention in the process.

History of Automation Engineering

The first to develop an interest in automating processes were the ancient Greeks, who developed a wide range of devices. Since these devices acted on their own, they were often called automata. The first known device with feedback control is the water clock developed by Ctesibius that was able to accurately maintain time. This water clock remained the most accurate time-keeping device until the invention of the pendulum clock in 1656 by Christiaan Huygens.

Control systems and automation developed after the invention of the steam engine and the Watt governor by James Watt.

By the 1950s, a new industrial revolution, often called the third Industrial Revolution or the Digital Revolution, had started. This revolution focused on the implementation and use of complex electrical circuits that can be used to quickly and efficiently perform complex processes. With the development of these circuits, it became easy and cost effective to implement automation in a wide range of different fields. From the perspective of automation engineering, the key event was the development of the programmable logic controller (PLC) that could be used to implement advanced control methods in an industrial setting. At the same time, there was an explosion of interest in a theoretical perspective on automation engineering, especially in areas of control and process optimization.

More recently, with the growth of interconnectedness and the development of smart technologies, some have proposed that a new industrial revolution is dawning. This has been called the 4th industrial revolution or Industry 4.0, which focuses on the development of self-functioning, interconnected systems in an increasingly globalized world.

The Key Concepts in Automation Engineering

The basic concept in automation engineering is a process or system. In automation engineering, a system consists of inputs, denoted , and outputs, . Inputs receive those variables whose change will lead to a change in the system. Inputs can be divided into two types: manipulative and disturbance. A manipulative input is an input whose value can be changed through some device (controlled). A disturbance input is an input whose value cannot be changed (uncontrolled). Similarly, outputs can be divided into two categories: observable or measurable and unobservable or unmeasurable. Observable or measurable outputs are those variables whose value can be measured or inferred using some device. Unobservable or unmeasurable objects are those that cannot be measured. Finally, we consider the states of the system, which are the internal variables that describe the behavior of the system.

A model of the system is a mathematical representation of the relationship between the inputs, outputs, and states. Eight components of a system:

- Actual Process: This represents the process under consideration.

- Sensors: The sensors provide the ability to measure the process and understand how the variables are changing.

- Actuators: The actuators allows the value of a variable to be changed.

- Automation Devices: The automation devices are the controllers and related components that are used to automate the process. Most of the time the automation hardware consists of computers and other digital devices, such as programmable logic controllers (PLCs) that implement the required functions.

- Environment: The environment represents everything that surrounds the system to be automated that can have an impact on the overall performance of the system.

- Automation Objectives

- Operators: The human component. The operators interact with the process through the human machine interface (HMI). An HMI provides two key functions. It allows the operators to see the important process values and to manipulate the process values.

- Disturbances: Disturbances are everything that can impact the system, but whose presence can not be directly controlled.

The system should be safe and robust.

Automation Engineering Framework

When solving an automation engineering problem, the following steps should be considered:

- Modeling of the process: develop appropriate model

- Analysis of the process: use model to analyze how system will behave under certain conditions

- Design of the Automation Strategy: Provides an appropriate automation strategy that attains the required information objectives.

- Validation of the Proposed Automation Strategy: Validated the proposed automation strategy using the process model.

- Implementation and Commissioning of the Proposed Automation Strategy: involves the implementation of the strategy in the real process.

The Automation Engineering Pyramid

The Automation-Engineering pyramid is an overall description of the way in which different automation strategies can be organized and structured. It examines two key components: speed of response, or how often the system is expected to respond to changes and process details.

- Level 5 - Enterprise Resource Planning (ERP) level: focuses on abstract analysis of the overall company strategies for dealing with the current market conditions

- Level 4 - Manufacturing Execution Level: This level consists of the specific strategies that allow for the overall plant/process to run. This includes such details as production planning, production data acquisition, organization or delivery orders, and deadline monitoring.

- Level 3 - Process Control Level: This level focuses on short-term production planning, quality control, and maintenance planning with an action horizon of at most days.

- Level 2 - Control Level: This level considers how to run the algorithms for controlling the process using the available process information on the time horizon of minutes or even seconds.

- Level 1 - Field Level: This level focuses on sensors and actuators. Information is actively exchanged with Level 2, using the field buses.

- Level 0 - Process Level: This level represents the actual process that is running in real time.

Instrumentation and Signals

The foundational component of any automation system is the instrumentation, that is, the sensors, actuators, and the computer hardware which together produce a stream of values, often called a signal, that can be used for subsequent processing.

Types of Signals

In automation engineering, signals can be classified using two domains: time and value. Each domain has two options: continuous and discrete. In general, a continuous signal can take any value within the set of (positive) real numbers, while a discrete signal can only take certain, specified values.

In the time domain, a signal is said to be continuous if there exists a signal value for any time , or, in other words, the signal can be written as a continuous function of . A signal is said to be discrete in the time domain, if it is only defined at certain values , where (or ).

Similar to the time domain, the value domain of the signal can be classified into continuous or discrete. A continuous value for a signal implies that the signal can take any real number. A discrete valued signal can only take specific values. Binary signals are often displayed using what is called a timing diagram. In a timing diagram, the binary signal is plotted as a function of time. By convention, a signal that is continuous in both the time and value domains is called an analogue signal, while a signal that is discrete in both the time and value domains is called a digital signal.

Converting from analogue to digital signal consists of three components: sampler, quantiser, and encoder. This process is often denoted as an analogue-to-digital (A/D) converter.

- The sampler samples the value of the analogue signal on a fixed frequency to convert the signal into the discrete time domain.

- The quantiser converts this sampled signal into the available closest value (quantum) to create a digital signal.

- The encoder simply encodes the digital signal into a given digital representation that can be used by the computer.

Sensors

A sensor is a device that can detect changes in a variable and upon calibration display these changes in a manner that can be understood by others, often with reference to some absolute scale. A sensor is characterized by two properties: accuracy and precision/reproducibility.

- Accuracy measure the ability of a sensor to give the

true

value, which is usually determined based on some standard. The difference between the true and measured values is often called bias. - Precision or reproducibility measures the variability of the sensor when measuring the same value. The variance of the sensor value should ideally be small.

- The range of the sensor is defined as the difference between the largest and smallest values that the sensor can measure.

Sensors need to be calibrated before being used or to check that they are behaving as expected. Calibration involves using standards with accurate and well-defined values to compare against the measured value given by the sensor. Plotting the measured and true values against each other will allow the calibration of the sensor to be determined. The two parameters of interest in the below calibration curve are the y-intercept, which gives the bias, and the slope of the line (or lack of linearity).

Pressure Sensor

In general, most industrial pressure sensors are constructed using a transducer that can convert the force per given area (pressure) into an electric signal. Nonelectric pressure sensors, often called manometers, do not produce an electric signal and often have a calibrated faceplate that allows the value to be read.

Gauge pressure is the pressure relative to atmospheric pressure. A negative gauge pressure is expressed by using the term vacuum.

Most transducer-based pressure systems use some type of electric circuit to measure the pressure on the system. Common strain gauges include piezoresistive, capacitive, electromagnetic, piezoelectric, and optical.

Liquid Level Sensors

Determining the liquid level in tanks or other similar containers is a very common need on many chemical plants. Liquid level can be determined using many different methods, including differential pressure cells, floats, and various radio-based methods. Of these, the most common approach is to use a differential pressure cell, which measures the pressure gradient between the top of the liquid and the bottom of the liquid.

Flow Sensors

Flow sensors are used to measure the speed at which a liquid or gas is moving. There are three main types of flow sensors:

- mechanical flow sensors

- Based on the idea of timing how long it takes the liquid or gas to fill some unit of volume. Most mechanical flow sensors have some type of wheel or paddle that is turned by the flowing medium inducing an electric signal, which is then calibrated to give a flow rate.

- pressure-based flow sensors

- Measure the pressure difference caused by some construction in flow to determine the flow rate.

- electromagnetic flow sensors

- Use various electromagnetic waves (including light) to measure the flow of the fluid.

Temperature Sensors

Temperature sensors are used to measure the temperature of a stream, be it liquid or gas. The most common industrial temperature sensor is the thermocouple, where temperature changes induce a voltage (called the Seebeck effect) in two different touching conductors. It is possible to calibrate this change with voltage and hence use it.

There exist various online sensors that can quickly provide readings for many different types of physical properties. Unfortunately, most of these sensors are relatively limited in their accuracy or precision. This often results from the extreme or nonideal conditions in which such systems are used.

Actuators

An actuator is a device that can change the amount of some variable that enters a system. An actuator is characterized by three properties: accuracy, precision or reproducibility, and performance. Accuracy measures the ability of an actuator to give the true

value, which is usually determined based on some standard. The difference between the true and measure values is often called bias. Precision measures the variability of the actuator when delivering the same value. There re three common actuators: valves, pumps, and variable current actuators.

Valves

Valves are one of the most common actuators seen in a plant. They allow the flow rate of a liquid or gas to be controlled. Since valves are so ubiquitous in plants, there is a vast amount of work done on understanding valves and how they impact the performance of automation. The most common type of control valve is a pneumatic control valve that uses air to change the flow rate. A pneumatic control valve consists of three components:

- the current-to-pressure converter (I/P) converter

- the valve itself

- a positioner

The I/P converter takes the electric 4-20mA signal and converts it to an appropriate pressure signal that can provide the motive force required to move the piston. There exist two types of control valves: air-to-close and air-to-open. Air to open valves are also called fail close valves because in the event of a loss of air pressure, the valve will close. Similarly, air-to-close valves are called fail open valves because in the event of a loss of air pressure, the valve will remain open.

For an air-to-close valve, the compressed air enters the top of the valve actuator, exerts force against the diaphragm, and moves the diaphragm until the resistance force from the spring is equal to the form on the diaphragm from the compressed air. An increase in air pressure will push the diaphragm down, while a decrease in air pressure will result in the spring forcing the diaphragm up to a new equilibrium point. The valve stem is attached to the diaphragm, and as the stem moves up and down it changes the position of the tapered plug relative to the seat.

For an air-to-open valve, the air enters on the bottom of the diaphragm, so an increase in air pressure will raise the diaphragm, thus opening the valve.

Many modern valves have an additional element called a positioner that seeks to overcome any potential errors in the valve.

The sizing of a control valve determines the range of flow rates over which the valve can produce a hydrodynamically stable flow.

Dynamic Performance of Valves

In most flow control applications, it is desirable for the flow through the valve to be a linear function of valve position, If a plot of valve %open as a function of steady-state flow rate produces a straight line, then the value is said to be linear. There exists two types of valves which will give a nonlinear plot: quick-opening valves and equal-percentage valves, whose plots are shown below.

- A quick opening valve, will quickly open and reach the maximal flow rate, while

- an equal percentage valve will reach the maximum flow rate more slowly,

The behavior of a valve is called the inherent valve characteristic.

Pumps

Another actuator that can control the flow rate in a stream is a pump. A pump is a mechanical device that takes a fluid, most often a liquid, from a storage tank and moves it to some other location. The main types of pumps are centrifugal pumps, positive-displacement pumps. and axial-flow pumps.

In centrifugal pumps, the flow direction changes by 90 as it moves over the impeller, while in axial-flow pump the flow direction is not changed. In positive-displacement pumps, the fluid is trapped in a fixed volume and forced (or displaced( into the discharge pipe. The most common type is the centrifugal pump.

Compared to valves, pumps tend to have better control of the flow rate and have fewer nonlinearity characteristics. However, they have much higher energy consumption than valves. The main considerations for a pump, as for valves, are sizing and performance.

The behavior of a pump is characterized by its pump characteristic curve, which is often supplied by the manufacturer of the pump. The head, , normally expressed in units of length, such as meters or feet, shows how high a given column of liquid could be lifted by a pump. It represents the effective pressure gradient that the pump can overcome. The efficiency, , represents how much work put into the pump is converted into lifting the liquid. For centrifugal pumps, the net positive suction head (NPSH) is the minimum head (pressure) at the inlet before cavitation occurs. Cavitation is defined as the boiling of liquid in a pump.

Programmable Logic Computer (PLCs)

Programmable logic computers (PLCs) are small computers that have been made robust and rugged. They are often used in industry for controlling processes, such as assembly lines, robots, or complex chemical processes. PLCs allow the collection of the different signals and their subsequent processing to reach a decision or action that may need to be taken.

PLCs consist of 6 key components:

- Inputs: Allow information from outside the PLC to be incorporated and used.

- Power Supply: This provides the power required to run the PLC and operate all the circuitry.

- Central Processing Unit (CPU): The CPU is the brain of the PLC that performs all the required instructions, calculations, and control functions.

- Memory: Stores relevant information for future use

- ROM: permanent storage for operating system and system data

- EEPROM: used instead of ROM in practice so that it is possible to update the operating system for the PLC

- RAM: used to store all other information required by the PLC including any programs and variables

- Communications Unit: The communications unit allows for the PLC to interact with other devices and exchange information using different types of protocols.

- Outputs: allow the PLC to exchange information with other devices to cause them to take an action.

In a PLC, communication between the components occurs using groups of copper wires called buses. A typical PLC consists of 4 buses:

- Data Bus: The data bus is used to transfer information between the CPU, memory, and I/O.

- Address Bus: The address bus is used to transfer the memory addresses from which the data will be fetched or which data will be written.

- Control Bus: The control bus is used to synchronize and control the traffic circuits.

- System Bus: The system bus is used for input-output communications.

The basic idea for a PLC is to monitor and control a process. A process is anything in this context that requires monitoring and control. In PLC terms, a process is said to be in a given operating mode, when the process is operating in some specified mode. The PLC requires a user program that takes the inputs, outputs, and internal information to make decisions about the process.

The operating modes for a PLC:

- programming: a PLC is being programmed, usually by an external device.

- stop: the PLC is stopped and will only perform some basic operations.

- error: the PLC has encountered some sort of problem and has stopped working.

- diagnostic: the PLC runs without necessarily activating any inputs or outputs, allowing for the validity of the program to be determined. Often, test signals are used in place of the real inputs and outputs.

- run: a PLC is actively working and performing the requested actions.

In run mode, the PLC performs the same four operations in a repeating cycle:

- Internal Processing: where the PLC checks its own state and determines if it is ready for operation,

- Reading Inputs: All input statuses are copied into memory.

- Executing Programs: The programs are executed in the order in which the code has been written.

- Updating Outputs: The output memory is written so that the state and values of the output can be updated.

By convention, a single pass through the four operations is called a scan or scan time or cycle time is the amount of time required to perform a single scan.

Three common execution tasks with which a program can be executed:

- Cycle Execution: the time between scans is fixed.

- Freewheeling execution: As soon as one scan has been completed, the next scan is started.

- Event-Driven Execution: In event-driven execution, a task is only executed when a given Boolean condition is fulfilled.

If a task can be interrupted, it is called pre-emptive; if it cannot be, nonpre-emptive.

Communication Devices

The last type of instrumentation is the communication devices which allow all actuators, sensors, and control logic to communicate with each other. The following equipment is found:

- Analogue-to-Digital Converters (A/D Converter), which convert the analogue signal received from the sensor into a digital signal. At this point, quantization can be an issue.

- Digital-to-Analogue Converters (D/A), which convert a digital signal received from the computer/software into an analogue signal that can be used by the actuator,

- Control Software

- Data Historian: stores all the values for future retrieval. Selecting an appropriate sampling time, or how fast the data are recorded, can determine the usefulness of the stored data for future applications.

- Network Cables, Switches, and Accessories, which physically connect all the equipment and allow for the strategy to be implemented.

The main issue with the design of the communication units is the available bandwidth. By using a live zero, that is, the value of zero corresponds to some nonzero current or pressure, means that it is possible to distinguish between the case of a zero value and a faulty device.

Mathematical Representation of a Process

In order to understand and provide useful information about a process, it is necessary to understand how different processes and systems can be represented. In practice, there exist two main types of representation: mathematical and schematic.

- A mathematical representation focuses on providing an abstract description of the process that provides information about the process. A good mathematical representation of the system can provide a deep understanding of how the system works and how it will behave in the future.

- On the other hand, a schematic representation focuses on the relationship between the different components and how they relate to each other. It is a visual approach that allows the actual process to be represented on a piece of paper.

Common mathematical representations include: state-space models, transfer function models, and automata.

Laplace and Z-Transforms

Two common transformations between the time and frequency domains: the Laplace and z-transform. If the time domain is continuous, then the Laplace transform is used, while if the time domain is discrete, the z-transform is used.

Laplace Transform

The Laplace transform converts a function from the time domain into the frequency domain. This transform allows for a simple algebraic solution of complex differential equations. Laplace transforms are widely used in automation engineering to understand process behavior and obtain solutions to various control problems.

The Laplace transform is defined as

where is the Laplace transform function, is the original function, and is the Laplace variable. Conventionally, the Laplace transform is denoted by a Faktur L, , that is . Converting from the frequency domain to the time domain is conventionally shown using the inverse of the Laplace transform, . Often, when we are given an equation in the Laplace domain, it may be necessary to convert it into the time domain. This can be done using the inverse Laplace transform, .

Z-Transform

The z-transform converts a discrete function from the time domain into the frequency domain. This transform allows for a simple algebraic solution of complex difference equations. Due to this feature, z-transforms are widely used in automation engineering to understand process behavior and obtain solutions to various control problems.

The z-transform is defined as:

where is the transformed function and the original discrete function.

Time and Frequency-Based Models

Time- and frequency-based models are one of the most commonly encountered mathematical representations of a process. Time-based models focus on the behavior of the system with respect to time, that is, how the system evolves or changes over time given specific inputs and states. However, since solutions can only be obtained by integrating the complex differential equations, recourse is often made to frequency-based models where it can be easier to understand how the process will behave when the inputs change.

Classifications of models

- Linear vs nonlinear: A model is said to be linear with respect to if the following statements hold:

- Principle of Superposition: and

- Principle of Homogeneity:

- Time invariant vs Time Variant: A model is said to be time-invariant if the parameters of the model are constant with respect to time

- Lumped parameter vs distributed parameter: A model is said to be a lumped parameter system if the model does not depend on the location, that is, there are no space derivatives present. A model that depends on the location (contains space derivatives) if called a distributed parameter system.

- Causal vs noncausal: A system is said to be causal if the future values only depend on current and past values. In a noncausal system, the future values depend on the current, past, and future values.

- System with memory (dynamic) vs system without memory (static): A system is said to have memory if the future values depend on both the past and present.

Time- and Frequency-Domain Representations

In automation engineering, there are two common representations of a system: state-space and transfer-function models.

The state-space model focuses on the relationship between states, inputs, and outputs in the time domain. The general state-space model is given as:

where is the state variable, u is the input variable, is time, is an output, and are some functions, and an arrow above denotes a vector.

- The state variable is a variable that describes the current location of the system from which the system's future behavior can be determined. A state variable will often appear in some equation as a derivative with respect to time.

- The input variable, , is a variable that describes the properties of a stream entering a system.

Traditionally, the number of inputs is denoted , the number of states by , and the number of outputs by . A system where is said to be univariate or single-input, single-output (SISO). If and are greater than 1, then the system is said to be multivariate or multivariate or multi-input, multi-output (MIMO). A system is said to be multi-input, single-output (MISO), if and .

The general state-space model is then reduced to a linear form:

where is the state matrix, is the input matrix, is the output matrix, and is the feed-through matrix.

The transfer-function representation focuses solely on the relationship between the inputs and outputs in the Laplace domain and allows easier analysis of the system than for a state-space model. The general transfer function representation can be written as:

where is a matrix containing the transfer functions of the model:

It is often assumed that each transfer function can be written as:

where and are polynomials of and is the deadtime or time delay in the system. The order of a transfer function is equal to the highest power of the -polynomial. A transfer function is said to be proper if the order of the numerator is less than or equal to the order of the denominator. A transfer function is said to be strictly proper if the order of the numerator is less than the order of the denominator.

A process is said to be causal if the time delay, (or ) is nonnegative; otherwise, the process is noncausal. In the discrete domain, causality is ensured by a proper transfer function. The poles of a transfer function are defined as the roots of the denominator, , that is, those values of such that =0. The zeros of the transfer function are defined as the roots of the numerator . A process is said to be at steady state if all derivatives equal 0:

If the above does not hold, the process is said to be operating in transient mode. It should be noted that small deviations from zero do not necessarily mean that the process is now in transient mode. In practice, it may mean that it may not be possible to achieve steady state, both due to continual small fluctuations and measurement imprecisions. In such cases, it is common to define the settling time, , of a process as the time it takes for the process to reach and stay within an envelope centered on the new steady-state value and has bounds that are 5% of the change in the process variable.

- The gain, K of the process represents the steady-state behavior of the system for a unit change in the input.

- The process time constant represents the transient or dynamic component of the system, that is, how quickly the system responds to changes in the input and reaches a new steady state value.

- The time delay, , measures how long it takes before the system responds to a change in the input.

Schematic Representation of a Process

A block diagram is an abstract way of representing a system in the frequency domain that allows for all the messy details to be hidden and only the essential elements shown. The basic block diagram consists of three parts, the input, the output, and the process model. Another common block is the summation block, which shows how two or more signals are to be combined. One of the most useful features of block diagrams is the ability to easily compute the relationship between the different signals.

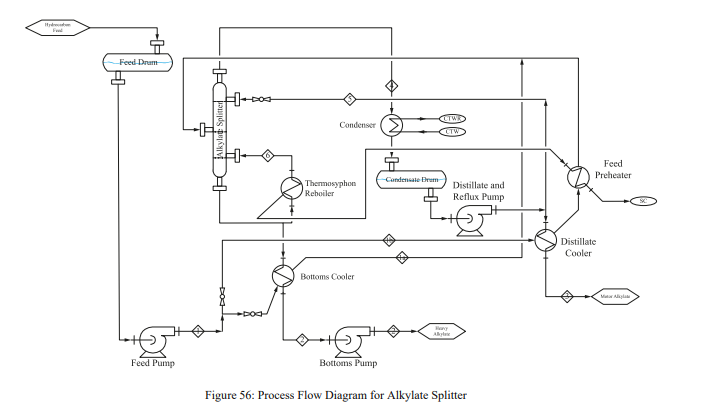

The process flow diagram is a simplified diagram of the process, where only the key components and connections are shown.

A process flow diagram for a single process normally contains the following elements: process piping, key components, key valves and control valves, connections to other systems, key bypass and recycle streams, and process flow names.

Control and Automation Strategies

The control or automation strategy is the method used to control/automate the process to achieve the desired objectives. The concept is to produce a system that can operate on its own with minimal human interface. Most common types of control strategies:

- Open-Loop Control: In open-loop control, the desired trajectory is set and implemented, The object follows this trajectory without taking into consideration any variations in the environment or surroundings.

- Closed Loop Control: In closed-loop control, the actual value of the system is always compared against the setpoint value. Any deviations are then corrected using a controller.

- Feedforward Control: In feedforward control, known disturbances are measured and corrective action is takes so that the disturbance does not impact the plant.

- Discrete-Event Control: In discrete event control, control only occurs when some logic condition is triggered.

- Supervisory Control: In supervisory control, the control loop does not control a process, but it controls another control loop.

Comments

You can read more about how comments are sorted in this blog post.

User Comments

There are currently no comments for this article.